Global Aerospace Titanium Market to Reach USD 6.68 Billion by 2032 on Aircraft Production Surge

Global Aerospace Titanium Market to Reach USD 6.68 Billion by 2032 on Aircraft Production Surge

Titanium remains a cornerstone material for aerospace innovation, balancing lightweight performance with durability as aircraft and defense platforms evolve.”

PUNE, MAHARASHTRA, INDIA, February 11, 2026 /EINPresswire.com/ -- Introduction of Aerospace Titanium Market— Fortune Business Insights

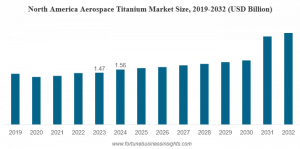

According to Fortune Business Insights, the Aerospace Titanium Market 2026 is witnessing strong growth due to increasing aircraft production, rising defense investments, and growing adoption of lightweight and high-performance materials across aerospace platforms. The global aerospace titanium market size was valued at USD 3.70 billion in 2024 and is projected to grow from USD 3.94 billion in 2025 to USD 6.68 billion by 2032, exhibiting a CAGR of 7.8% during the forecast period.

Aerospace titanium plays a vital role in aircraft structures, engines, spacecraft, and defense systems due to its exceptional strength-to-weight ratio, corrosion resistance, and thermal stability. The increasing integration of titanium alloys in next-generation aircraft and space exploration systems is significantly accelerating global market demand.

Get Sample Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/aerospace-titanium-market-114582

Aerospace Titanium Market Snapshot

2024 Market Size: USD 3.70 billion

2025 Market Size: USD 3.94 billion

2032 Forecast Market Size: USD 6.68 billion

CAGR: 7.8% (2025–2032)

Major Application: Aircraft structures and engines

Leading Platform Segment: Commercial aviation

Aerospace Titanium Market Size

The aerospace titanium market size is expanding steadily due to increasing aircraft manufacturing and the growing shift toward fuel-efficient and lightweight materials. Titanium is extensively used in airframes, landing gear components, compressor blades, hydraulic systems, and fasteners, where durability and fatigue resistance are essential.

The rising adoption of additive manufacturing and near-net-shape forging technologies is further enhancing titanium utilization by minimizing material waste and enabling complex aerospace component designs.

Aerospace Titanium Market Share

The aerospace titanium market share is primarily driven by commercial aviation, supported by growing global passenger traffic and fleet expansion. Titanium’s compatibility with composite materials makes it a preferred metal for hybrid aircraft structures.

By alloy grade:

Ti-6Al-4V holds the largest share due to superior mechanical strength and corrosion resistance

Other advanced titanium alloys are gaining adoption for specialized aerospace applications

Aerospace Titanium Market Growth

The market is projected to grow at a CAGR of 7.8% during 2025–2032, driven by:

Increasing aircraft production and fleet modernization programs

Rising defense and hypersonic vehicle development investments

Expansion of reusable launch vehicle and space exploration programs

Growing demand for sustainable and fuel-efficient aircraft materials

Market Dynamics

Market Drivers

Rising Aircraft Production and Sustainable Material Adoption

Increasing production of commercial and defense aircraft is significantly driving titanium demand.

Titanium improves fuel efficiency through weight reduction

Growing adoption in widebody and next-generation aircraft

Increasing emphasis on net-zero aviation and sustainable aerospace materials

Market Restraints

High Processing Cost and Energy-Intensive Production

Titanium manufacturing involves complex and costly extraction and machining processes.

The Kroll process requires high energy consumption

Titanium machining generates high scrap rates

Limited global raw material suppliers increase procurement risks

Market Opportunities

Rising Investments in Hypersonic and Space Programs

Expanding global investment in reusable launch vehicles and hypersonic platforms is creating strong growth opportunities.

Titanium performs effectively under extreme temperature and stress conditions

Increasing transition from aluminum and nickel-based alloys to advanced titanium alloys

Aerospace Titanium Market Trends

Integration of Titanium Alloys with Composite Aircraft Structures

Modern aircraft manufacturers are increasingly combining titanium alloys with composite materials to enhance performance.

Improved fatigue resistance and structural strength

Enhanced corrosion resistance and thermal compatibility

Increased use in aircraft fuselage frames, landing gear, and engine pylons

Aerospace Titanium Market Segmentation Analysis

By Alloy Grade

Ti-6Al-4V

Largest market share

Used extensively in engines, airframes, and structural components

Ti-3Al-2.5V

Growing adoption in hydraulic tubing and aircraft structures

Other Alloy Grades

Used in specialized aerospace and defense applications

By Type

Plate Segment

Largest share due to high demand in airframe and engine structures

Bars Segment

Expected to grow significantly

Used in landing gear, actuator housings, and structural components

By Technology

Forging

Dominant segment due to superior fatigue resistance and structural integrity

Powdering (Additive Manufacturing)

Fastest-growing segment

Supports weight reduction and complex aerospace part production

By Application

Aircraft Structures

Largest market share

Used in fuselage, landing gear, and fastening systems

Aircraft Engines

Fastest-growing segment

Used in compressor blades, discs, and turbine components

Spacecraft and Missiles

Increasing adoption in next-generation defense and space programs

By Platform

Commercial Aviation

Largest market share due to growing aircraft orders and fleet expansion

Space Systems

Expected to witness rapid growth

Driven by reusable rocket and satellite constellation development

By End User

OEMs

Largest segment due to rising aircraft and engine production

MROs & Aftermarket

Fastest-growing segment

Increasing demand for replacement parts and aircraft maintenance

Aerospace Titanium Market Regional Outlook

North America

Dominates global market with strong OEM presence and defense procurement

Growing titanium production capacity and advanced manufacturing technologies

Europe

Significant growth driven by aerospace manufacturing and defense modernization

Increasing adoption of circular titanium and additive manufacturing technologies

Asia Pacific

Fastest-growing region

Rising air traffic, aircraft manufacturing expansion, and government aerospace initiatives

Increasing domestic titanium production capabilities

Latin America

Steady growth driven by expanding aerostructure manufacturing and MRO facilities

Middle East & Africa

Growth supported by commercial aviation expansion and defense modernization programs

Competitive Landscape

Key Industry Players

The aerospace titanium market is highly competitive, with companies focusing on advanced alloy technologies, production capacity expansion, and strategic supply agreements with aerospace OEMs.

Key Aerospace Titanium Companies

VSMPO-AVISMA Corporation

ATI Inc.

Titanium Metals Corporation (TIMET)

Precision Castparts Corporation

Toho Titanium Co., Ltd.

Osaka Titanium Technologies Co., Ltd.

Carpenter Technology Corporation

BaoTi Group Co., Ltd.

Key Industry Developments

May 2025: ATI signed a multi-year titanium supply agreement with Airbus

April 2025: Airbus secured titanium sourcing partnership with Saudi Arabia

April 2024: Airbus Aerostructures partnered with Norsk Titanium for titanium parts production

September 2023: AMG Critical Materials partnered with TIMET to establish titanium melt facility

Get Sample Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/aerospace-titanium-market-114582

About Us

Fortune Business Insights delivers detailed aerospace and defense industry research with actionable intelligence, technological insights, and strategic market forecasts. Our reports help manufacturers, suppliers, and investors identify growth opportunities, manage supply chain challenges, and adopt advanced aerospace material technologies to support future aviation and defense innovations.

Ashwin Arora

Fortune Business Insights™ Pvt. Ltd.

+1 833-909-2966

sales@fortunebusinessinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.