Arc-Flash Resistant Technical Yarn Systems Market Growth Accelerates Across APAC, Europe, USA, and Saudi Arabia

MD, UNITED STATES, February 6, 2026 /EINPresswire.com/ --

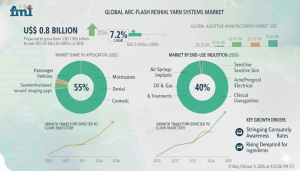

The global arc-flash resistant technical yarn systems market is entering a decade of structural transformation, projected to grow from USD 0.8 billion in 2026 to USD 1.6 billion by 2036, according to a new forecast by Future Market Insights (FMI). This expansion reflects a steady 7.2% CAGR, driven by tightening electrical safety regulations, grid modernization, and rising exposure to high-energy electrical environments across utilities, power generation, and heavy industrial sectors.

Rather than being driven by incremental material upgrades, market growth is increasingly anchored in baseline safety spending. Arc-flash protection is transitioning from a discretionary compliance measure to a permanent risk-management requirement embedded into industrial operating standards.

Electrical Safety and Multi-Hazard Protection Drive Structural Demand

Procurement behavior across the arc-flash resistant technical yarn systems market is being reshaped by stricter enforcement of electrical safety codes and rising incident-energy exposure. End users in utilities, power generation, infrastructure, and heavy manufacturing are narrowing specifications toward yarn systems that provide certified, multi-hazard protection while maintaining wearer comfort, flexibility, and long-term durability.

Rather than relying on fabric-level treatments, buyers are shifting upstream toward yarn-level engineering, where arc ratings, flame resistance, tensile strength, and cut protection are integrated directly into the fiber system. This ensures consistent protection across repeated laundering cycles and extended duty use, reducing performance drift and compliance risk.

Industry Realignment and Capital Reallocation Reshape Supply Chains

This structural shift is reorganizing how capital and capabilities are deployed across the advanced materials value chain. Large industrial groups are carving out high-performance fiber operations into more focused business units, allowing targeted investment in arc-rating performance, mechanical strength, and regulatory readiness.

Honeywell’s October 2024 decision to separate its Advanced Materials business reflects this logic, positioning specialty fibers as core growth assets rather than ancillary operations. Similarly, Teijin Frontier’s expansion of high-performance yarn production capacity in Southeast Asia highlights how suppliers are aligning production footprints with rising global demand for certified electrical safety apparel.

"2026 will be an exciting year as we move forward the final stages of our portfolio simplification. This positions each business with the right strategic focus, organizational agility, and tailored capital allocation strategies needed to grow faster and drive incremental value for all stakeholders."

(Source: Honeywell Reports Fourth Quarter 2025 Results; Issues 2026 Outlook)

Regulatory Compliance and Non-PFAS Innovation Gain Priority

Regulatory and materials compliance pressures are reinforcing demand for next-generation yarn systems. Producers are redesigning arc-flash and flame-resistant yarns to eliminate PFAS and halogenated chemistries, anticipating tighter state-level restrictions and evolving certification standards.

Milliken & Company’s late-2024 launch of a non-PFAS, non-halogenated protective yarn system illustrates how regulatory readiness is becoming a qualification filter alongside arc ratings and supply reliability. Leadership in this market is increasingly defined by execution discipline, integrated system design, and regulatory foresight, rather than isolated material innovation.

Aramid-Based Yarns Set the Performance Benchmark

Aramid-based yarn systems continue to define the performance benchmark, accounting for approximately 38% of total market share in 2026. These materials are valued for their non-melting behavior, high strength-to-weight ratio, and thermal stability above 500°C, aligning with regulatory expansion that mandates inherent flame resistance for a broader industrial workforce.

Protective Garments Dominate Application Demand

Protective garments represent around 50% of total market demand, serving as the primary channel through which technical yarn innovation reaches end users. This segment is driving development of lighter, multi-hazard garment systems that maintain high arc ratings while reducing wearer fatigue.

Hybrid yarn architectures combining high-tenacity filaments with flame-resistant spun yarns are enabling protection levels of 40 Cal and above, while preserving flexibility and comfort for extended field operations.

Utilities and Power Sector Sets Specification Standards

Utilities and power account for approximately 44% of end-use demand, exerting the strongest influence on material specifications. Ongoing grid upgrades, renewable energy integration, and stricter arc-flash labeling requirements under updated electrical codes are pushing utilities toward long-term supply agreements tied to certified yarn-system performance.

The 2026 update to the National Electrical Code (NEC) is accelerating this shift by tightening arc-flash labeling rules and requiring PPE arc ratings to align precisely with calculated incident energy levels. This is institutionalizing periodic reassessment of arc-flash risk and creating recurring replacement demand for certified yarn systems.

United States Leads Structurally Resilient Growth

The United States is emerging as the most structurally resilient growth market, supported by tightening enforcement of NFPA 70E and OSHA electrical safety provisions. The U.S. market is projected to expand at an 8.5% CAGR from 2026 to 2036, driven by recurring compliance cycles and long-term utility safety programs.

Request for Sample Report | Customize Report |purchase Full Report -https://www.futuremarketinsights.com/reports/sample/rep-gb-31850

Competitive Landscape and Market Evolution

The competitive ecosystem is shifting from fiber-led rivalry toward system-level competition. Differentiation is increasingly based on qualification continuity, regulatory readiness, and supply reliability, rather than arc performance alone.

Leading companies such as Kaneka Corporation, Teijin Aramid B.V., DuPont de Nemours, Toray Industries, Lenzing AG, Kordsa Teknik Tekstil, and Mount Vernon Mills are strengthening positions through capacity expansion, sustainability-linked innovation, and portfolio realignment.

Explore More Related Studies Published by FMI Research:

Battery Powered Surgical Drill Market-https://www.futuremarketinsights.com/reports/battery-powered-surgical-drill-market

Cytotoxic Chemotherapy Market-https://www.futuremarketinsights.com/reports/cytotoxic-chemotherapy-market

Targeted Oncology Biologics Market-https://www.futuremarketinsights.com/reports/targeted-oncology-biologics-market

Chaperone-based Therapeutics Market-https://www.futuremarketinsights.com/reports/chaperone-based-therapeutics-market

Substrate Reduction Therapies Market-https://www.futuremarketinsights.com/reports/substrate-reduction-therapies-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why FMI: Decisions that Change Outcomes- https://www.futuremarketinsights.com/why-fmi

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-347-918-3531

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.